Engineering students across the globe often get their first exposure to 3D CAD tools in college. For many, the default software is Solidworks, thanks to its long-standing presence in educational programs. But what happens when these students graduate and enter professional environments with more complex and rapidly evolving needs? Enter Creo and Creo+—PTC’s robust suite of CAD solutions designed for advanced design, simulation, and manufacturing. In this post, we’ll discuss why Creo, with its industry-leading capabilities, offers college engineers a chance to thrive. Additionally, we will explore why engineering organizations should consider the switch, despite the objection that “college kids are taught Solidworks.”

Solidworks: An Educational Standard but Not the Whole Picture

Solidworks has been a staple in many colleges for years. It’s known for its ease of use and offers a solid foundation for budding engineers. However, its primary focus is on basic CAD functions, which can limit its application in advanced engineering roles. While it’s great for teaching design basics, Solidworks isn’t equipped to handle the end-to-end product development demands that are increasingly necessary for today’s complex engineering projects. When these college engineers transition to professional roles, they often find that they need to switch from Solidworks to more advanced tools to meet industry requirements. Not to mention that many companies are being pushed to move to Dassault’s 3DX platform. This is resulting in a lot of changes for what graduates would be using anyway. This is where Creo comes in.

Why Creo and Creo+ Are Ideal for College Engineers and Beyond

Creo and Creo+ aren’t just CAD tools—they are complete engineering solutions. Here’s why they provide a significant advantage over Solidworks for engineers.

1. Advanced Capabilities

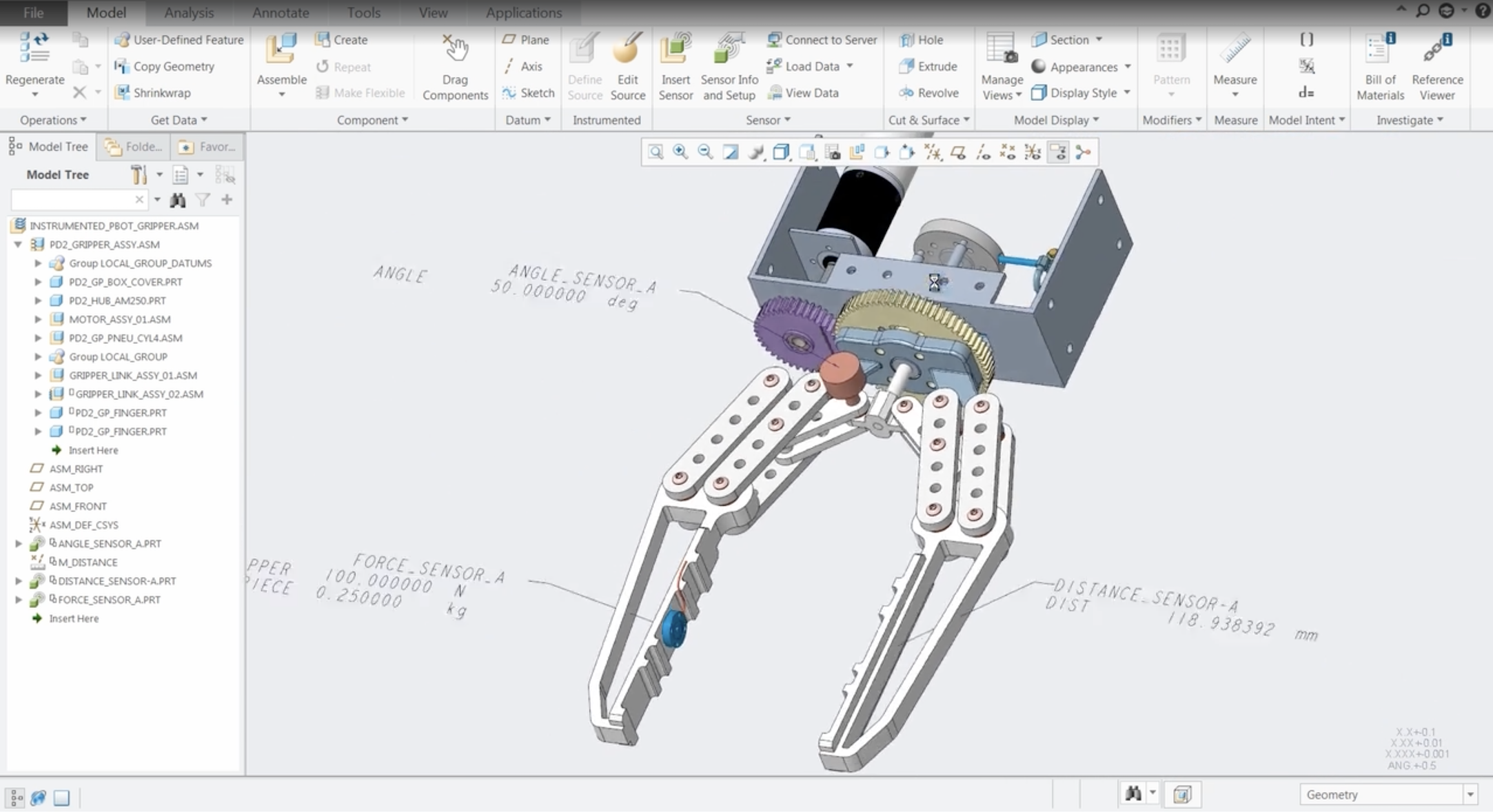

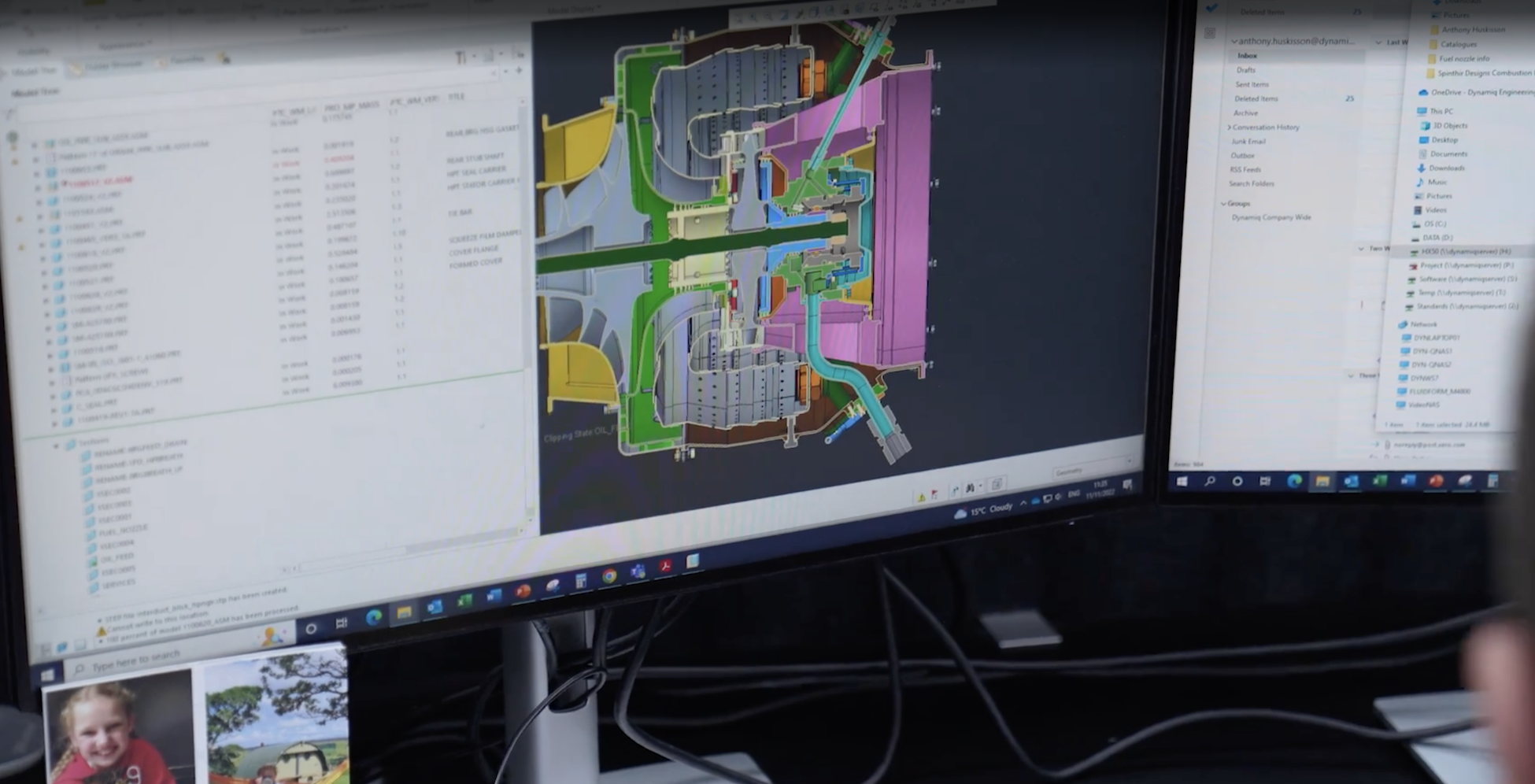

Creo offers more comprehensive tools, from parametric design and simulation to augmented reality (AR) and model-based definition (MBD). This makes it ideal for industries like aerospace, automotive, and medical devices, where accuracy and innovation are crucial.

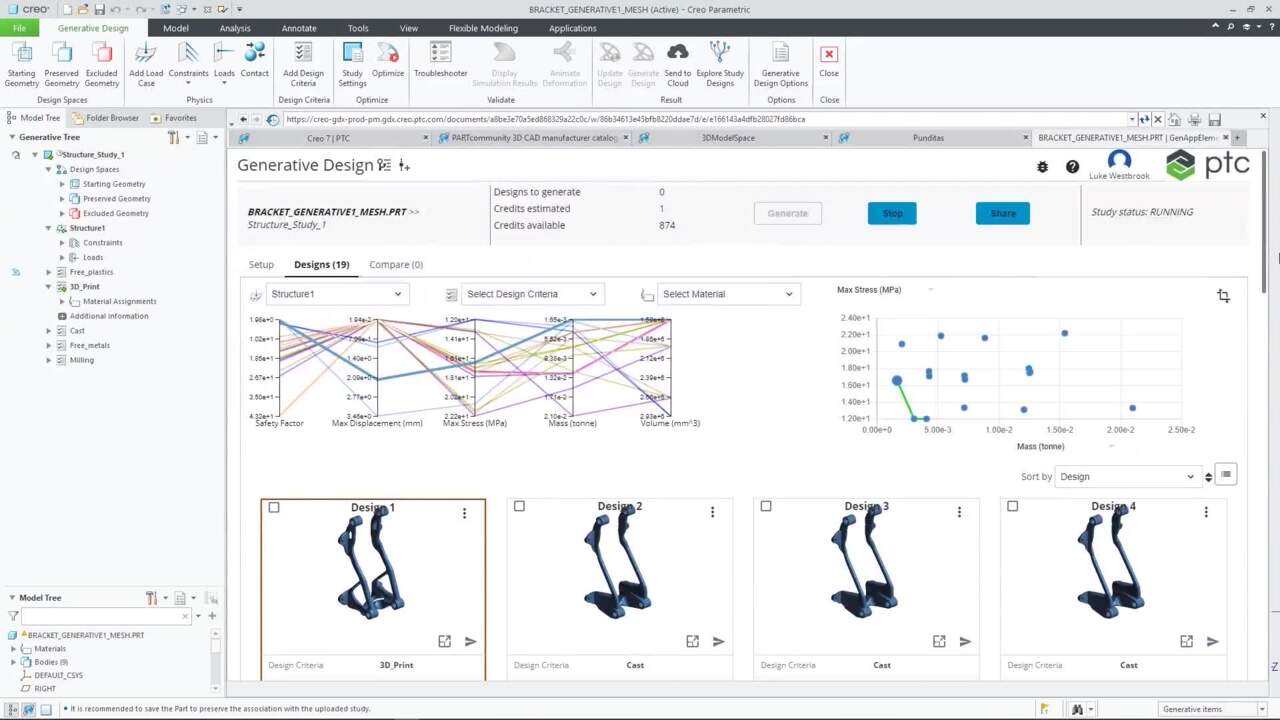

2. Integrated Simulation and Generative Design

With built-in simulation, Creo enables real-time analysis, allowing engineers to refine designs without the need for separate software. Solidworks, on the other hand, often requires additional add-ons to achieve the same functionality. Creo also boasts generative design tools that allow engineers to explore optimized designs based on constraints like weight and material strength.

3. Scalability

As engineers progress in their careers, they will likely need to engage with more sophisticated design challenges. Creo scales from initial concept design to full-scale production, seamlessly handling advanced tasks like additive manufacturing and IoT integration.

4. Cloud-Based Creo+

The introduction of Creo+ brings CAD to the cloud, supporting real-time collaboration and improved design iteration. This makes it particularly appealing for new engineers who thrive in digital, team-oriented environments.

PTC’s Investment in Early Engineering Education

PTC has made a strategic investment in nurturing young engineering talent through its various programs. These programs are designed to introduce students to industry-grade software earlier in their education, helping them build skills that translate directly to professional applications. They’ve even created videos and free software downloads for students to get started in Creo, Onshape, and other products. These initiatives are crucial in changing the paradigm of engineering education. They ensure that the next generation of engineers enters the workforce with skills that are directly relevant to today’s engineering challenges.

A Case Study for Creo at Purdue University

PTC recently hosted its annual event at Purdue Polytechnic’s new Smart Learning Ecosystem, showcasing how PTC software like Creo, Windchill, and Vuforia integrates with Purdue’s hands-on manufacturing labs. The event allowed PTC employees and customers from industries like automotive and medicine to see Purdue students using PTC tools in real-world scenarios. Purdue’s facilities, which include the Smart Learning Factory and the Industrial IoT Lab, focus on replicating real-world production environments to prepare students for the workforce.

PTC’s collaboration aims to teach future engineers advanced skills and foster innovation. Furthermore, it emphasizes the benefits of seeing PTC tools used beyond a controlled headquarters setting.

Students work in the Industrial IoT lab. (Purdue University photo/John O’Malley)

Investing in Creo Means Investing in the Future

While college engineers often start with Solidworks, switching to Creo is a strategic investment for organizations seeking to build cutting-edge products and foster engineering innovation. By adopting Creo, you’re not just choosing a tool. Instead, you’re enabling engineers to excel with more advanced features, integrated simulations, and future-ready capabilities like AR and IoT.

If you want to see how Creo can transform your engineering team’s capabilities, consider starting a pilot program similar to PTC’s work with high schools and universities like Purdue. It’s time to let engineering teams thrive with tools beyond what they learned in college. To get started with Creo, contact our experts today.