PTC’s Windchill is one of the leading PLM solutions, with many organizations trusting Windchill to manage their product data. Product Lifecycle Management software solutions are not scarce, so what makes Windchill stand out from the rest of the market? If you are looking for a direct comparison, here are some blogs comparing it to other popular solutions:

If instead, you are looking to research Windchill’s capabilities and explore use cases, this is the blog for you.

Windchill’s Objective

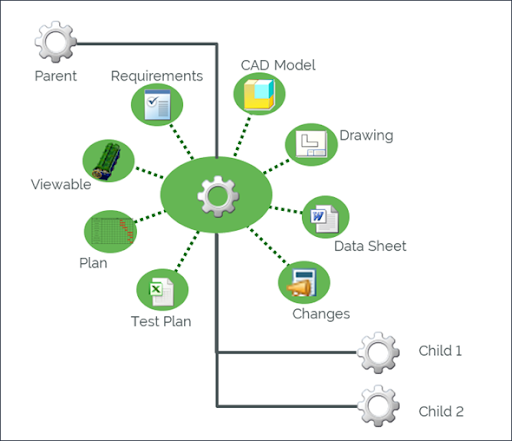

Windchill is a PLM software that manages product data and facilitates data visibility, traceability, and collaboration during the product lifecycle. It is described as an “out-of-the-box” system as it offers a range of readily available functionalities. Its goal is to streamline product life cycle management by fostering communication, documenting requirements and modifications, and providing helpful visualization tools.

Windchill’s Core Features

Windchill manages every facet of the product lifecycle. Let’s dive into the features that allow it to do this.

Component Management

Windchill offers component management capabilities that allow users to manage all the parts that make up a product. Users can create, organize, and track the lifecycle of each component. Additionally, users can reuse parts and documents by classifying them into different schemas. Reusing these records on new projects can improve productivity and product quality while lowering costs. In addition to these capabilities, component management can include BOM management, variant management, and supplier management. A great example of component management in action is during manufacturing, users can manage each specific component used in product assembly.

Product Data Management (PDM)

In addition to component management, Windchill offers product data management capabilities. PDM can become an issue when diversified engineers or teams try to access the same data. Windchill resolves this problem by offering a central source for all product data. This ensures team members have access to all the information needed to effectively collaborate without overwriting one another’s changes. This information can include CAD files, BOMs, and other product data documents including manufacturer and vendor information. This centralized system increases efficiency and collaboration and reduces search time and errors for team members.

Change Management

Change management is an important part of PLM. Windchill offers change management tools to initiate, track, and implement changes to products. Additionally, Windchill’s flexible workflows ensure the proper tasks are given to the correct user, streamlining the configuration process. Users can also validate changes and create reports detailing the modifications. These features allow teams to visualize and understand their changes and increase enterprise value.

Supplier Management

In addition to change management, Windchill offers features for supplier management. Windchill allows users to manage relationships between their Approved Manufacturer and Vendor Lists (AMLs/AVLs). They are offered a portal to view supplier information, communicate about product parts, and share documents with suppliers. Windchill also helps track compliance information, ensuring AMLs act within industry standards.

BOM Management

As mentioned previously, Windchill offers Bill of Materials (BOM) management. With this capability, users can document and maintain all the product data throughout the product lifecycle. A Bill of Materials lists all the components and materials required for product assembly. Windchill allows users to assign attributes to components within BOMs including descriptions, quantities, and part numbers. Additionally, Windchill offers BOM configuration, allowing users to revise BOMs and manage BOM variants. If needed, users can also export BOM data for distribution to manufacturers or other organizations involved in the PLM process.

Visualization

Windchill offers useful visualization capabilities that facilitate communication amongst teams. Users can view and annotate 2D and 3D CAD models to suggest changes or offer feedback. Additionally, Windchill offers version comparison so users can track differences between product versions and ensure design consistency. These tools improve the efficiency of the design review process, which this webinar showcases.

Requirements and Test Management

In addition to visualization tools, Windchill has requirements and test management capabilities that allow users to organize and maintain product requirements. This captures the voice of the customer, aligning customer needs with development efforts. The product requirement tools also reduce the time to document requirements and minimize issues in the process. Additionally, Windchill offers automated validation of product designs and software, allowing them to be validated before production. These tools permit users to verify the adherence to quality management best practices. Users can also manage test sessions and ensure test results meet expectations. These features help improve product quality and streamline the testing process.

Quality Management and Compliance

Maintaining customer satisfaction is important, but adhering to quality management standards is equally important. Windchill offers a wide range of quality management features allowing users to ensure products meet compliance and quality standards. Users can monitor product quality during each step of the product lifecycle. Additionally, users can document any certifications and regulatory approval records within Windchill’s secure environment.

Integration

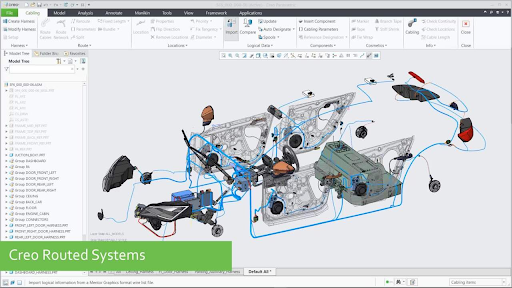

In addition to Windchill’s amazing internal capabilities, Windchill can also seamlessly integrate with other enterprise systems. Integrating with ERP and CRM systems provides a solid foundation for a product-driven digital thread. Additionally, Windchill enables CAD integration with products such as PTC Creo, Solidworks, and Autodesk Inventor. This allows users to manage CAD files directly in Windchill. Windchill can also integrate with other PLM software and ALM tools, improving collaboration and requirements management capabilities. Lastly, Windchill provides integration frameworks allowing organizations to develop custom integrations with third-party systems.

Why Windchill?

Windchill is amazing for the product digital thread, not just because of its capabilities, but also due to its technology partner ecosystem. Windchill allows organizations to connect, integrate, and manage data across the value chain. Its out-of-the-box functionality provides for an optimized user experience, but its expansive customization and configurability means it can adapt to almost any process or need. Additionally, Windchill can be hosted by SPK and associates, making it a SaaS model that allows data to be securely shared with external partners. Windchill has an extensive technology partner ecosystem including CAD, ERP, supply chain, and simulation partners. As far as partner integration and overall capabilities go, Windchill is an amazing choice for a PLM solution.

Get Started with Windchill

Now that you have explored Windchill’s long list of features, you may be interested in learning more. SPK has experts available to answer any questions for you. If you would like to get started with Windchill or have any questions regarding PLM, contact our experts today.