Manufacturing can be an intricate and time-consuming process. It is important to utilize the proper software for successful execution, especially when working with complex assemblies. Complex assemblies typically have a high part count of diverse components and require a high level of precision and accuracy. PTC’s Creo is the perfect CAD software for this kind of assembly, as it has an advanced assembly extension entitled Creo AAX. This extension provides advanced tools that simplify assembly design and management.

Capabilities of Creo AAX

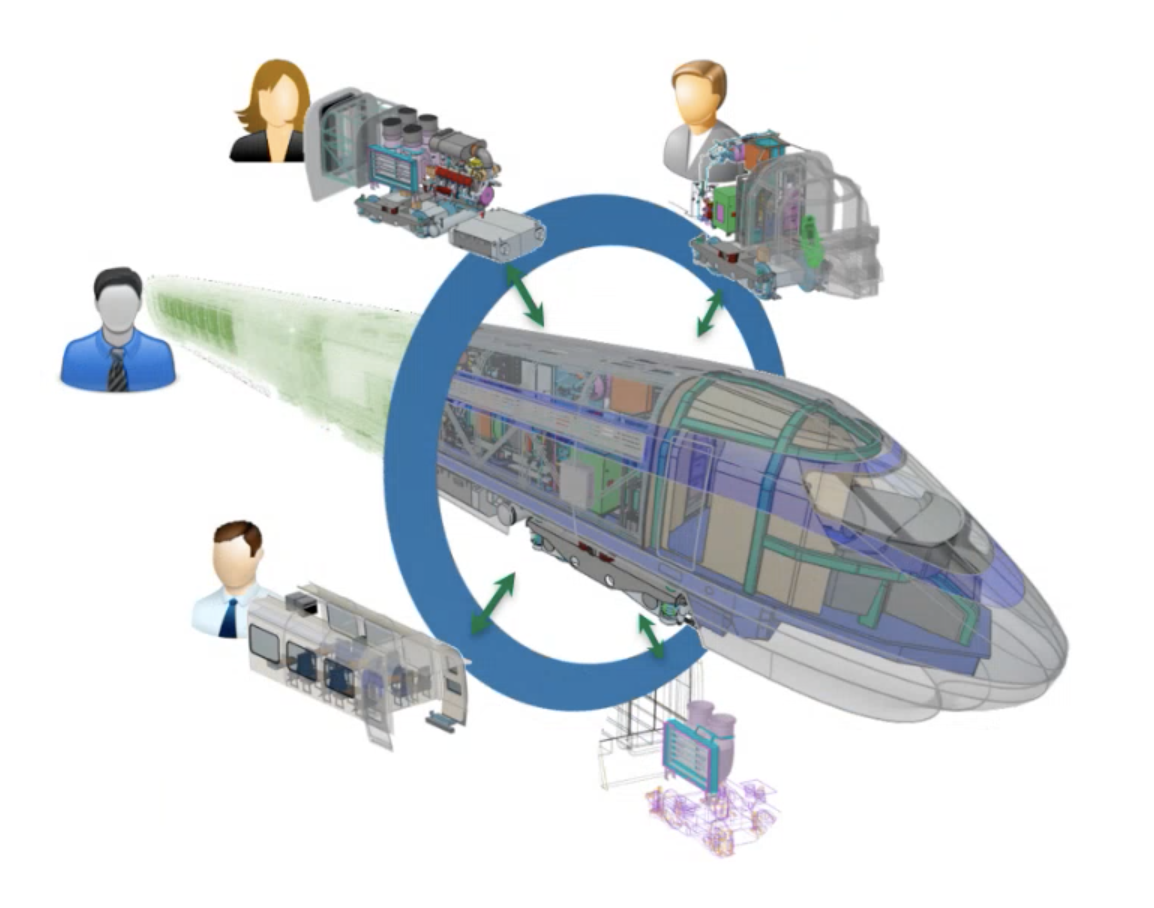

The Creo Advanced Assembly Extension utilizes advanced tools to optimize the manufacturing process. Overall it streamlines production by providing ways for engineers to easily collaborate.

Here are some of Creo AAX’s main capabilities:

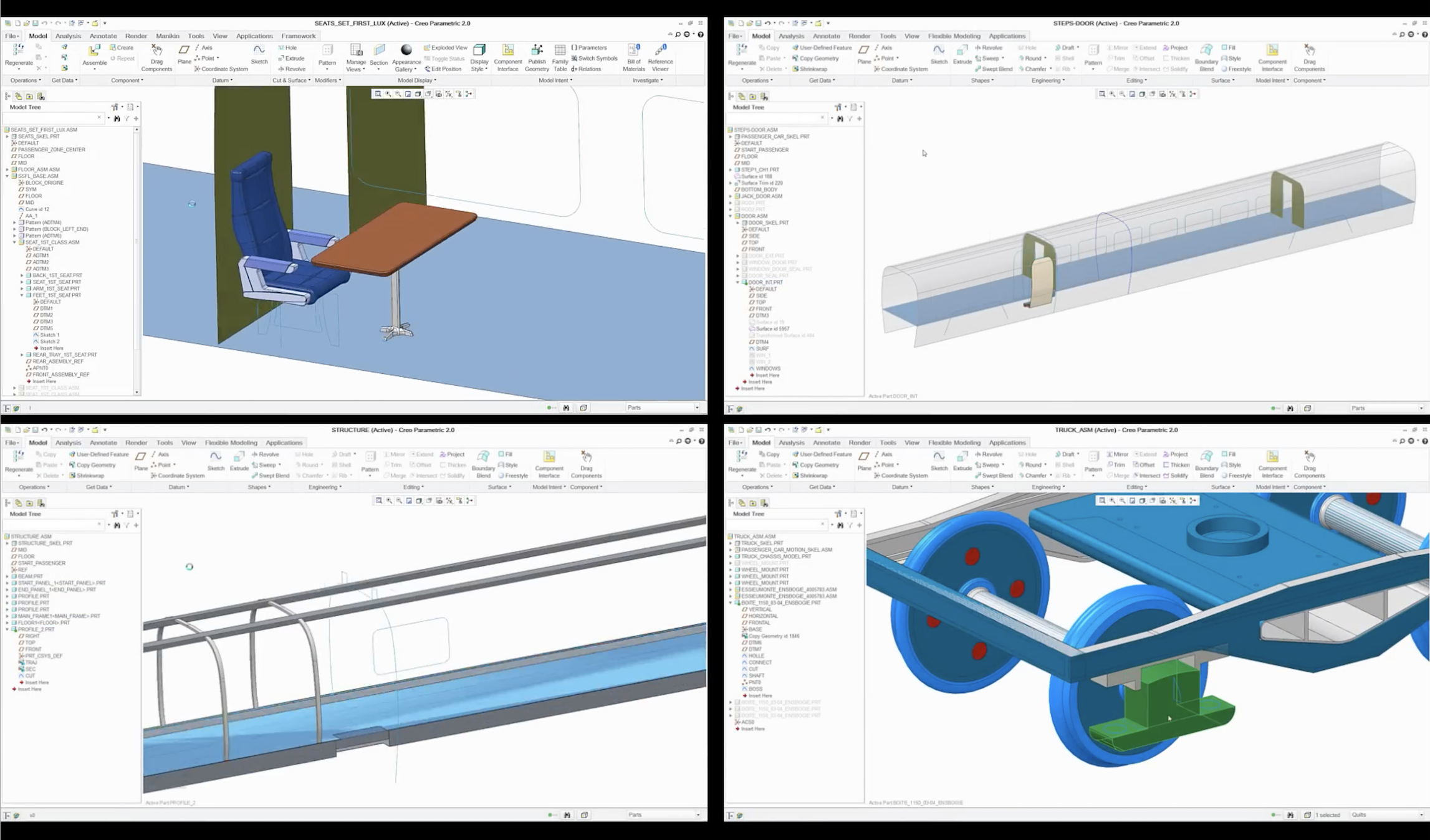

- Top-down Design: Creo AAX supports a top-down approach that defines the overall structure and critical assembly features first. This approach simplifies the relationships between components, allowing for a simple assembly process.

- Process Planning: Manufacturers can process plan with Creo AAX which helps them decide the sequence of operations to assemble a product or part. This is great for collaboration.

- Concurrent Engineering: Also known as simultaneous engineering, this approach allows engineers to work on different assembly parts at the same time. It allows for simultaneous work as opposed to typical consecutive work.

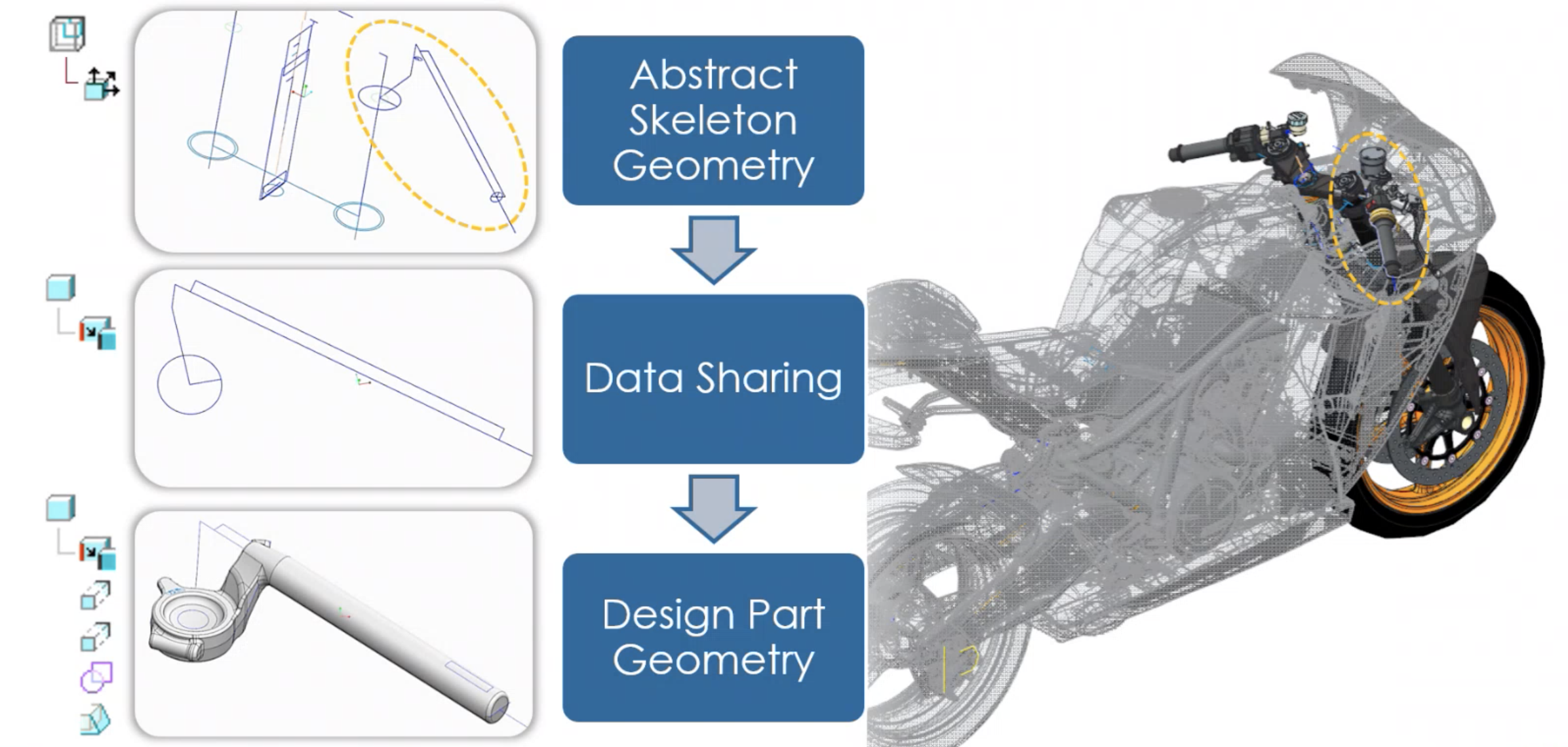

- Skeleton Models: Users can create skeleton models that serve as a framework for the assembly. These models define key geometry to capture and manage design intent, ensuring consistency across the assembly.

- Interchange Assemblies: AAX supports interchange assemblies which allow designers to quickly switch between different versions or configurations of an assembly. This capability is particularly useful in scenarios where multiple product variants are being developed.

- Design Automation: AAX allows users to automate repetitive design tasks, which reduces the potential for errors. For example, designers may create reusable design templates or automate the generation of standard components.

- Shared References: Users can create, link, or reference elements between different components of a CAD project with AAX. This ensures changes made to one part are reflected in other parts.

All of these features make complex assembly management simple.

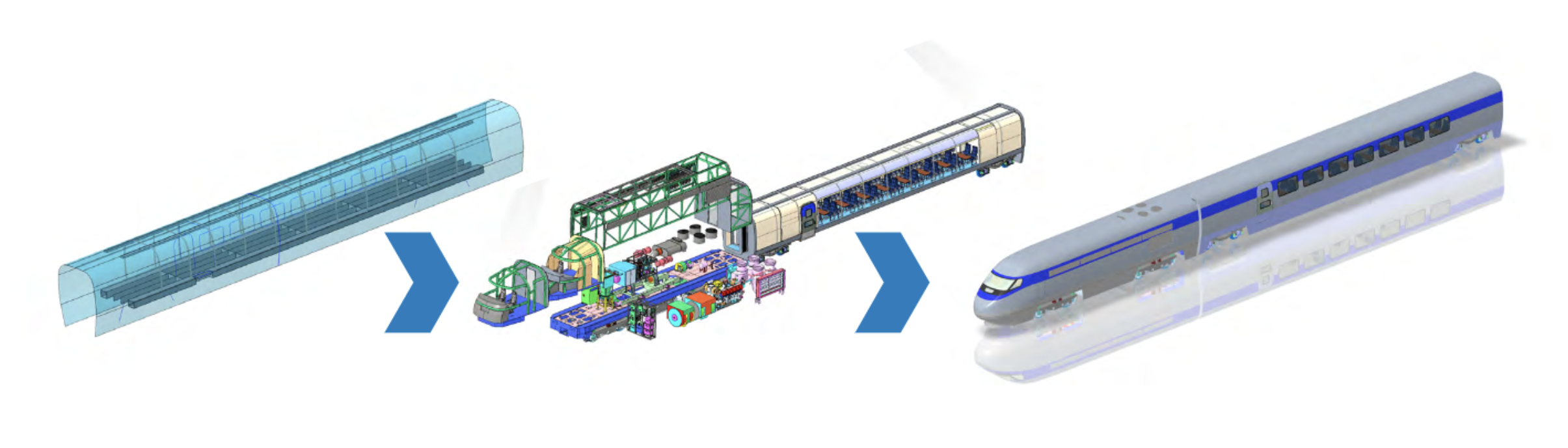

Creo AAX for Complex Assemblies

Creo AAX is particularly well-suited for complex assemblies due to its robust set of features and capabilities. These capabilities are made to handle intricate and large-scale designs. The first feature, concurrent engineering, allows users to work quickly and efficiently. It reduces the product development cost and time-to-market. Additionally, Creo AAX’s capabilities reduce design errors and increase product quality. Manufacturers can create more designs within a shorter time frame, leading to increased innovation. Furthermore, the Advanced Assembly Extension supports build-to-order initiatives. These initiatives help develop and define new product markets.

Creo AAX’s top-down design features like skeleton models and data-sharing allow users to ensure collaboration and consistency. Users may easily make changes throughout the assembly structure or even create simplified envelope parts. These parts are then used to improve assembly performance. Additionally, some processes may be automated, simplifying the production process and reducing errors. Creo AAX’s reference capabilities are also great for complex assemblies. Users can specify global scope and object-specific scope settings for external references. These references are used to ensure consistency amongst parts. All of these features make Creo AAX a valuable tool for engineers and designers working on complex assemblies. Its advanced features optimize designs, reduce development time, and improve overall product quality.

Implementing Creo AAX

If you want to learn more about Creo AAX or would like to read about companies that have successfully implemented it, download this pdf. Creo AAX is particularly beneficial for the manufacturing of automotive, aerospace, and industrial equipment parts. Its top-down design, automation, and reference capabilities make it an amazing tool for complex assemblies like these. If you have questions or want to get started with Creo AAX, contact our experts today.