In the current competitive market, innovation and quality are the primary drivers for gaining market share. To remain competitive, companies must design and deliver products that exceed performance standards while balancing cost and production efficiency. Achieving this is possible with the proper design software. PTC’s CAD solution Creo offers an array of capabilities that empower companies to design and manufacture products with a competitive edge.

Understanding Design Needs

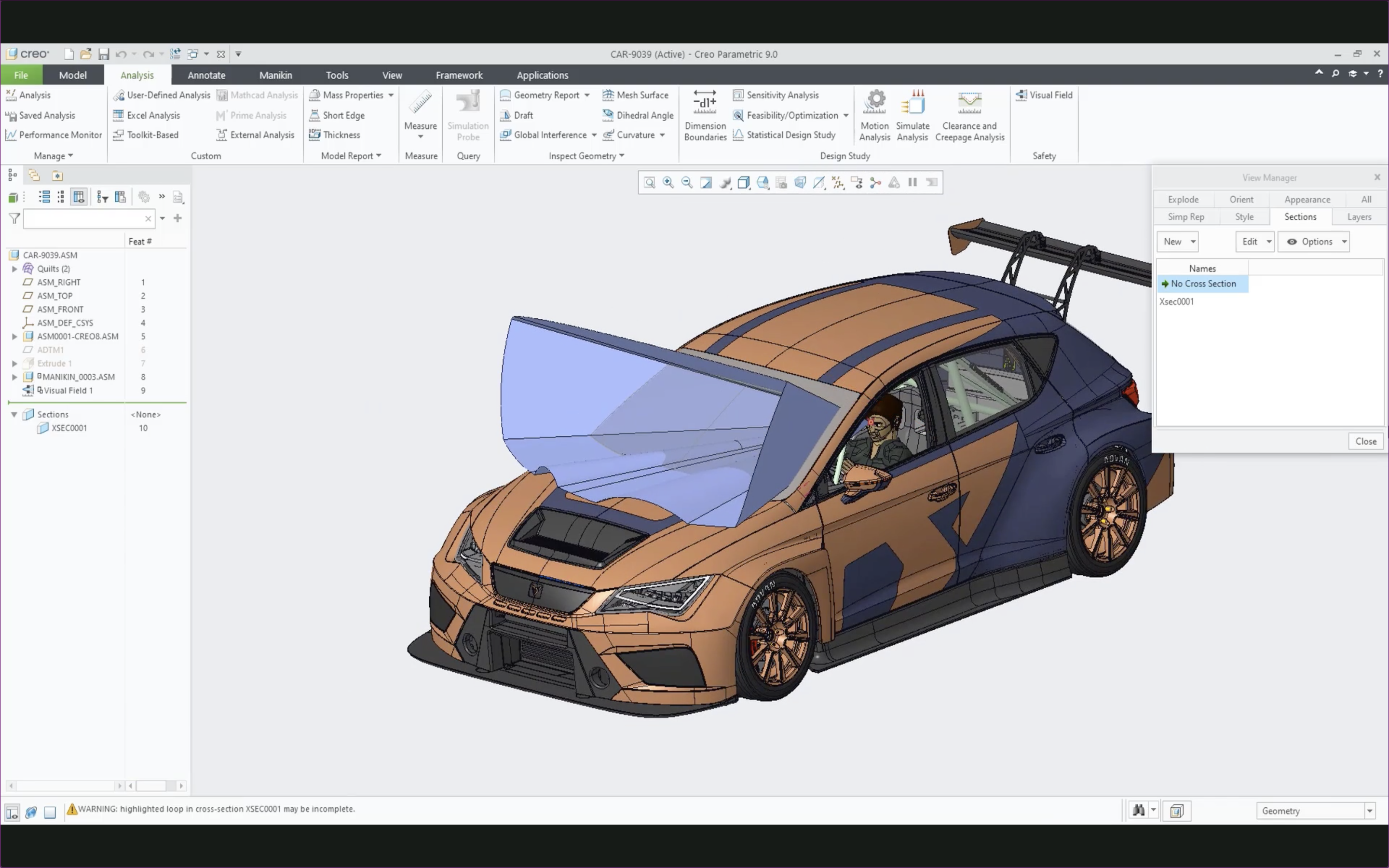

To ensure successful product development, designers must first understand and acknowledge their design needs. Does their company typically design and assemble components to meet specifications or integrate parts sourced from suppliers? Differences like these are important to acknowledge as certain systems work better for certain scenarios. Fortunately, Creo excels in both cases by allowing design teams to manage complex assemblies that include in-house designs, as well as third-party components from suppliers.

Furthermore, Creo seamlessly handles third-party data by easily integrating 3D models in various file formats without losing data integrity. Engineers can make edits or updates to this imported data, enabling design modifications and iterations without the need to recreate models from scratch. This ensures flexibility in the design process which helps achieve customization and maintain production timelines.

Quality, Performance, and Durability with Creo

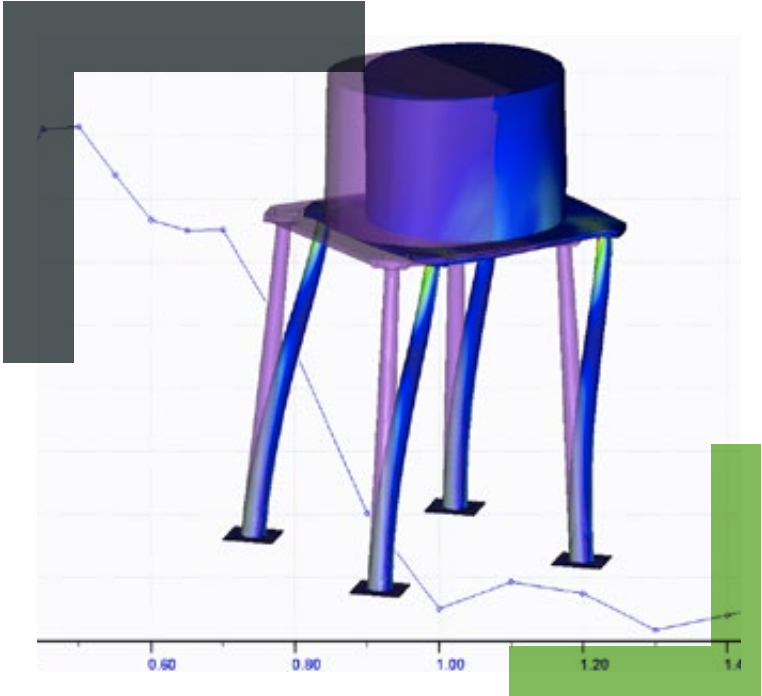

As stated before, innovation and quality are the driving forces of design success. So, for many companies, the competitive edge lies in delivering products that excel in quality, performance, and durability. Creo’s capabilities help engineers design and optimize products to meet and exceed these criteria by offering advanced simulation and analysis tools. Its built-in simulation capabilities show engineers how components will perform under various conditions. If properly tested, the resulting product can be extremely durable. This ensures failures due to heat, fatigue, or other conditions do not occur. Furthermore, iterating designs through simulation allows engineers to fine-tune products to ensure they meet quality and durability standards.

Aesthetics as Key Differentiators

One of the most popular differentiators in consumer products apart from quality is aesthetics and styling. While some industries such as medical device manufacturing may focus less on what a product looks like, and rather on what it does, industries such as automotive manufacturing must also consider how their products look. Creo’s powerful surfacing tools allow users to create complex and visually appealing products. Engineers and designers can explore a wide range of material, shape, and color options, ensuring that their products appeal to consumer preferences. In addition to this, Creo also enables real-time visualization which allows designers to evaluate how different material and color choices impact the product’s final appearance. Overall, Creo helps companies achieve competitive differentiation by ensuring products are not only high quality, but also align with branding and customer expectations.

Additive Manufacturing and Composite Design in Creo

When designing innovative products, companies often aim to improve performance. Alterations like strength and weight reduction are important for industries like aerospace and automotive. Reducing weight can lead to better fuel efficiency and performance, as well as make the product more sustainable. Creo’s composite design allows users to design with composites and other lightweight materials. It also has dedicated tools for lattice structures which are used to create lightweight yet strong components.

Creo also supports additive manufacturing which allows engineers to design parts optimized for 3D printing. For example, engineers may create complex lattice geometries or internal cooling channels, which are impossible to manufacture with traditional methods. This gives companies greater flexibility in prototyping and production, allowing for faster iterations and innovation cycles.

Regulatory Compliance

While quality, aesthetics, and material are all vital parts of the design process, compliance gains trust with customers. Meeting industry-specific safety standards is simple with Creo’s advanced failure analysis tools, such as Finite Element Analysis (FEA). FEA allows engineers to predict how products will perform under extreme conditions and ensure that they meet safety regulations. Engineers can mitigate risks early in the design process, resulting in a safer, more efficient product.

Integrating Design and Manufacturing

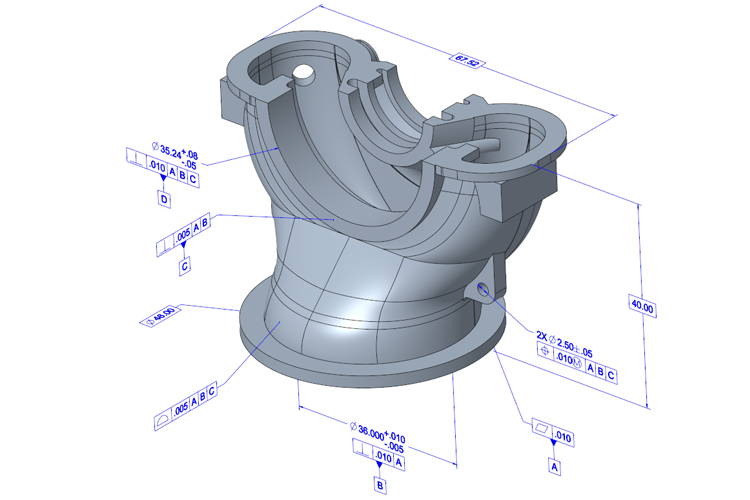

The last way to gain market share is to seamlessly integrate your design and manufacturing processes. Integrating these leads to faster time-to-market and higher product quality due to better traceability. Creo’s model-based definition (MBD) capabilities allow design teams to create comprehensive digital models that include all necessary manufacturing details. This reduces errors, speeds up the handoff between design and manufacturing, and ensures that products are built according to the exact specifications. In addition to this, Creo’s simulation abilities ensure that designs can be efficiently produced with minimal rework, leading to faster production cycles and lower costs.

Implementing Creo in a Competitive Market

To remain competitive, companies must ensure quality, innovation, style, and compliance. Creo’s flexible features help designers achieve all of this, setting it apart from other CAD solutions. From concept design to post-production, Creo’s advanced capabilities ensure your product rises above the competition. If you would like to learn more about Creo, contact our experts.