Change management, though necessary, can often be a difficult process involving multiple teams and data handoffs. Managing product, system, and process changes to meet organizational goals doesn’t have to be complicated. Utilizing a PLM solution such as PTC Windchill can enable organizations to streamline their processes, resulting in lowered costs, higher quality, and accelerated time-to-market. Let’s explore how Windchill’s automated change management capabilities can benefit organizations.

The Challenges of Manual Change Management

Manufacturers without a robust change management system often struggle with slow, inefficient processes. These can include unnecessary meetings and manual handovers. Systems like this are prone to errors, as they lack visibility. This disconnect can lead to production delays, increased costs, and diminished product quality.

For example, misconfigured processes often introduce new problems rather than improve product quality. Additionally, poorly managed systems diminish productivity due to stakeholders having to spend more time on administrative tasks. Furthermore, miscommunication caused by these systems can lead to rework. Poor change management also leads to wasted time and effort, delaying product launches. Windchill PLM addresses these challenges by automating the change process and providing real-time visibility.

Change Management with Windchill

Windchill empowers manufacturers by delivering efficient change management. From the initial change request to the final product release, Windchill’s features streamline every stage of the process. First and foremost, Windchill is configurable, allowing businesses to tailor workflows to their specific needs. Additionally, Windchill provides real-time visibility into requested changes to ensure stakeholders are well-informed. Furthermore, Windchill enables users to track and validate changes, ensuring they meet regulatory standards before implementation. With all of this to say, one of the most significant benefits of Windchill’s change management system is its ability to create a single source of truth. The PLM system ensures all product data remains accurate and up to date, which reduces errors and miscommunication.

Key Features of Windchill Change Management

Windchill’s comprehensive features support a structured change management process that aligns teams. The following features can improve product quality and get products to market quicker.

- Change Workflows: Customizable workflows enable teams to accelerate product development while maintaining full visibility of in-process work. Furthermore, automated task assignments ensure the timely completion of critical tasks.

- Change Impact Analysis: Windchill’s change impact analysis helps users identify all the objects affected by a change. Whether it affects one simple drawing or a complex system architecture, this approach ensures that teams can assess the full scope of a change before implementing it.

- Change Redlining: Redlining capabilities allow users to easily flag suggested changes to BOMs. This enables a clearer understanding of how affected objects relate to the final product.

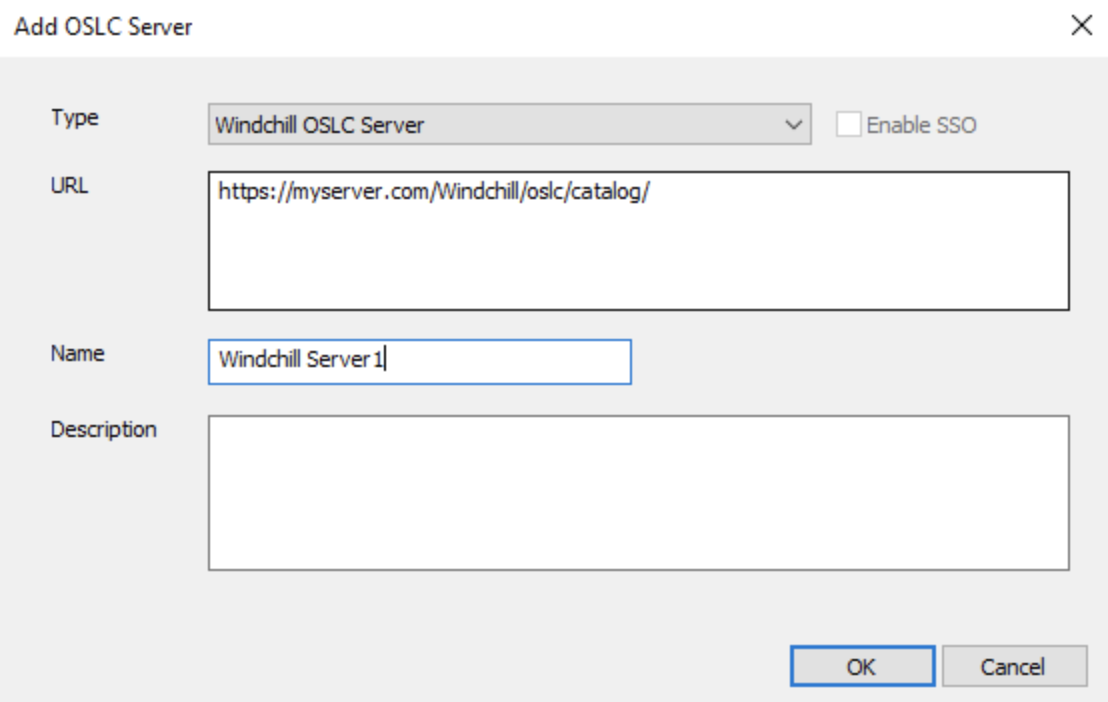

- Digital Product Traceability: Windchill leverages Open Services for Lifecycle Collaboration (OSLC) to create traceable links across systems. This feature enhances collaboration by connecting product data from tools like Codebeamer to system models in the Windchill Modeler. Tracking changes across systems ensures products maintain compliance.

- Change Notices & Requests: Windchill provides a structured system for evaluating change requests and change notices. This formal process ensures that changes are well-documented, properly reviewed, and consistently communicated across the enterprise.

Benefits of Windchill PLM

Windchill PLM’s advanced change management capabilities offer many benefits for manufacturers. Automating the change processes reduces the time required to develop products, leading to a faster time-to-market. Additionally, Windchill manages all data, ensuring it is accurate and synchronized across systems. This improves the quality of the data and reduces unnecessary revisions. Lastly, Windchill enables collaboration and provides better change visibility for all stakeholders. This visibility reduces the risk of producing products which leads to less rework.

Manage Changes with Windchill

Effective change management is critical for modern manufacturers, and Windchill PLM offers a robust solution. With Windchill, engineers can ensure all stakeholders remain aligned and that changes are implemented efficiently and accurately. If you are ready to streamline change management, contact our experts about Windchill today.