A delayed product launch can mean more than a simple setback in the modern competitive market. It can result in missed revenue, frustrated customers, and even potential damage to a company’s reputation. Businesses must understand and anticipate these costs of delays and prioritize their development efforts to stay competitive. In this blog, we will explore the importance of CoD and WSJF prioritization and how solutions like PTC’s Creo and Windchill PLM can help reduce delays, bringing products to market faster.

The Disadvantages of Product Launch Delays

Delayed product launches disrupt carefully planned schedules and create significant setbacks for businesses. These delays are often caused by disconnected systems and processes which lead to:

- Internal and Customer Line Failures: Late detection of design issues can lead to product failures either internally or at the customer level, resulting in additional delays and high repair costs.

- Increased Rework: Disconnected processes create gaps in product data, often leading to production errors, costly rework, and a higher likelihood of field failures.

- Missed Market Opportunities: Competitors may fill the market gap if a company can’t release its product on time, leading to lost revenue and reduced market share.

The longer a product’s release is delayed, the greater the risk of losing potential profits, customer satisfaction, and brand credibility.

Cost of Delay (CoD) and Weighted Shortest Job First (WSJF)

When developing products, prioritizing tasks effectively is key to ensuring timely delivery. When implemented correctly, using the Cost of Delay (CoD) and Weighted Shortest Job First (WSJF), as practiced in the Scaled Agile Framework (SAFe) ensures proper prioritization.

Cost of Delay (CoD)

CoD measures the potential value lost by delaying a job, feature, or task. It helps teams understand the financial or strategic impact of waiting to complete a specific piece of work. Estimating CoD allows decision-makers to make informed choices about which tasks should be prioritized to minimize potential loss.

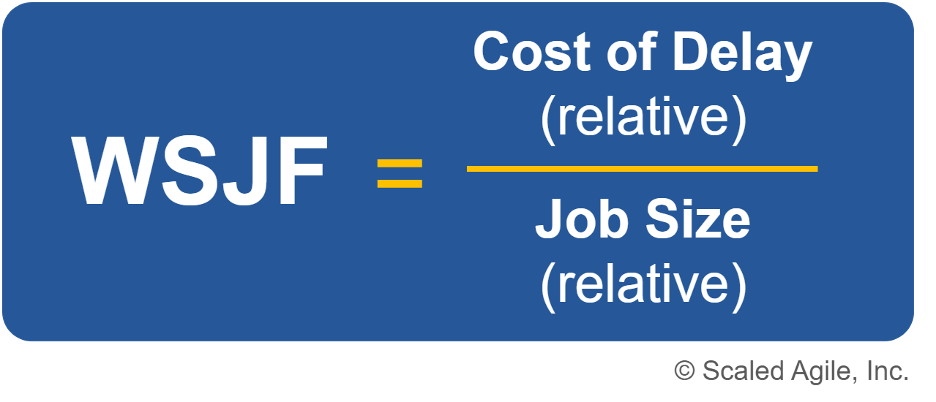

Weighted Shortest Job First (WSJF)

WSJF is a prioritization model that sequences tasks based on the greatest economic value they can deliver in the shortest time. In the SAFe model, WSJF is calculated by dividing the CoD by the duration of the task. This method continuously prioritizes tasks to yield the best economic outcomes. WSJF ignores sunk costs, uses relative cost estimates, and focuses on the economic value rather than just the return on investment. By applying WSJF, teams can sequence jobs in a way that maximizes economic impact. When combined with agile methodologies, this approach helps organizations pivot to high-priority tasks more effectively, reducing delays and enhancing productivity.

How PTC Solutions Support Faster Product Development

PTC solutions such as Creo and Windchill PLM, help organizations address the inefficiencies and miscommunication that commonly lead to product delays. They work together to streamline the product development process and minimize risks. Creo’s 3D CAD capabilities enable designers to quickly develop complex designs from concept to manufacturing. These capabilities help identify issues early in the design phase which avoids costly rework. In addition to Creo’s design capabilities, Windchill offers centralized data management which ensures teams have access to the latest information. A single source of truth eliminates duplicate work and communication gaps which makes accessing correct information quick and easy. Both of these solutions help avoid issues that can cause frustrating product delays.

Regulatory Requirements and WSJF Implementation

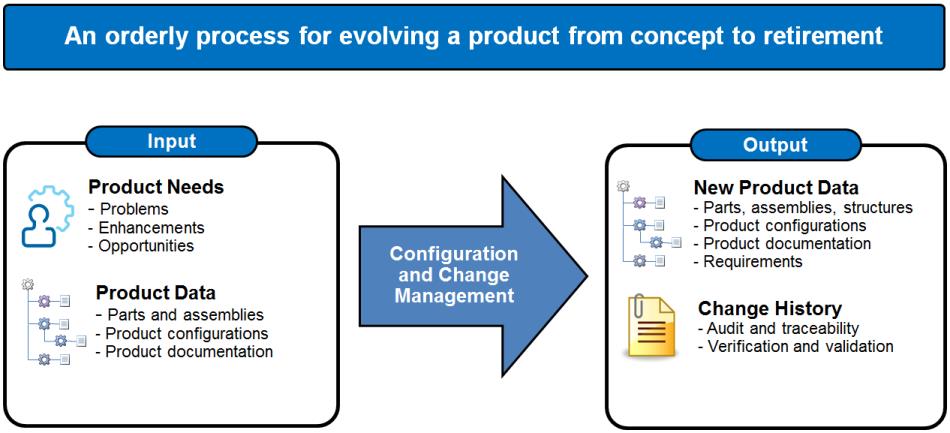

Along with eliminating issues, Windchill also offers integrated change management capabilities that allow teams to control changes across the product lifecycle. Stakeholders can stay informed of revisions, reducing any miscommunication that causes delays. Furthermore, Windchill automates compliance documentation, helping companies avoid setbacks from not meeting regulatory requirements. Both Creo and Windchill facilitate collaboration across teams and optimize workflows, helping get products to market faster. Lastly, integrating WSJF prioritization with PLM processes allows companies to use CoD to sequence their tasks in Windchill. This maximizes productivity, delivering the greatest value to product manufacturers. Overall, Creo and Windchill offer features and workflows that support timely and efficient product delivery.

Ready to Eliminate Product Delays?

The true cost of delays in product launches extends beyond immediate financial losses, impacting customer satisfaction and brand trust. By understanding the Cost of Delay and utilizing WSJF prioritization, companies can make data-driven decisions to maximize their economic outcomes. Implementing these practices with the right tools brings products to market faster and more efficiently. For organizations looking to reduce delays and improve product quality, integrating Creo and Windchill PLM into their development processes offers a powerful solution. If you want to learn more about the Scaled Agile Framework or PTC products, contact our experts.