When developing products, there are many components to keep track of such as parts, data, and configurations. Keeping up with every minor alteration to a product can be difficult, but using a PLM system like PTC Windchill can help you stay organized. Configuration management combined with PLM enables organizations to increase efficiency throughout the product development process.

Configuration Management in Product Development

Configuration management ensures that different versions of products are traceable across the entire lifecycle. This “single system” approach eliminates issues caused by fragmented data, empowering teams to deliver a consistent product to customers. Organizations can unlock several benefits by shifting from outdated, disconnected documentation to part-centric PLM.

Using the part-centric method, all information is visible at the part level. This eliminates the guesswork that comes with relying on outdated documentation. The latest, most accurate product data is always accessible. Additionally, when 2D drawings define products, this leads to silos of often outdated information. Part-centric PLM eliminates the challenge of synchronizing up-to-date data across departments. Lastly, defining the product through its parts rather than drawings allows changes to become more visible across all steps of the development process. This ensures accuracy across the product lifecycle.

Windchill’s End-to-End Configuration Management Capabilities

Windchill is equipped with an array of features that streamline configuration management and product development. Firstly, Windchill allows users to manage changes across the product lifecycle. Features such as interference detection prevent design conflicts and ensure compliance. Additionally, Windchill helps improve component and supplier management by tracking supplier relationships and preferences. Let’s dive deeper into how Windchill’s powerful features can streamline your product development.

Model-Based Design and AR in Configuration Management

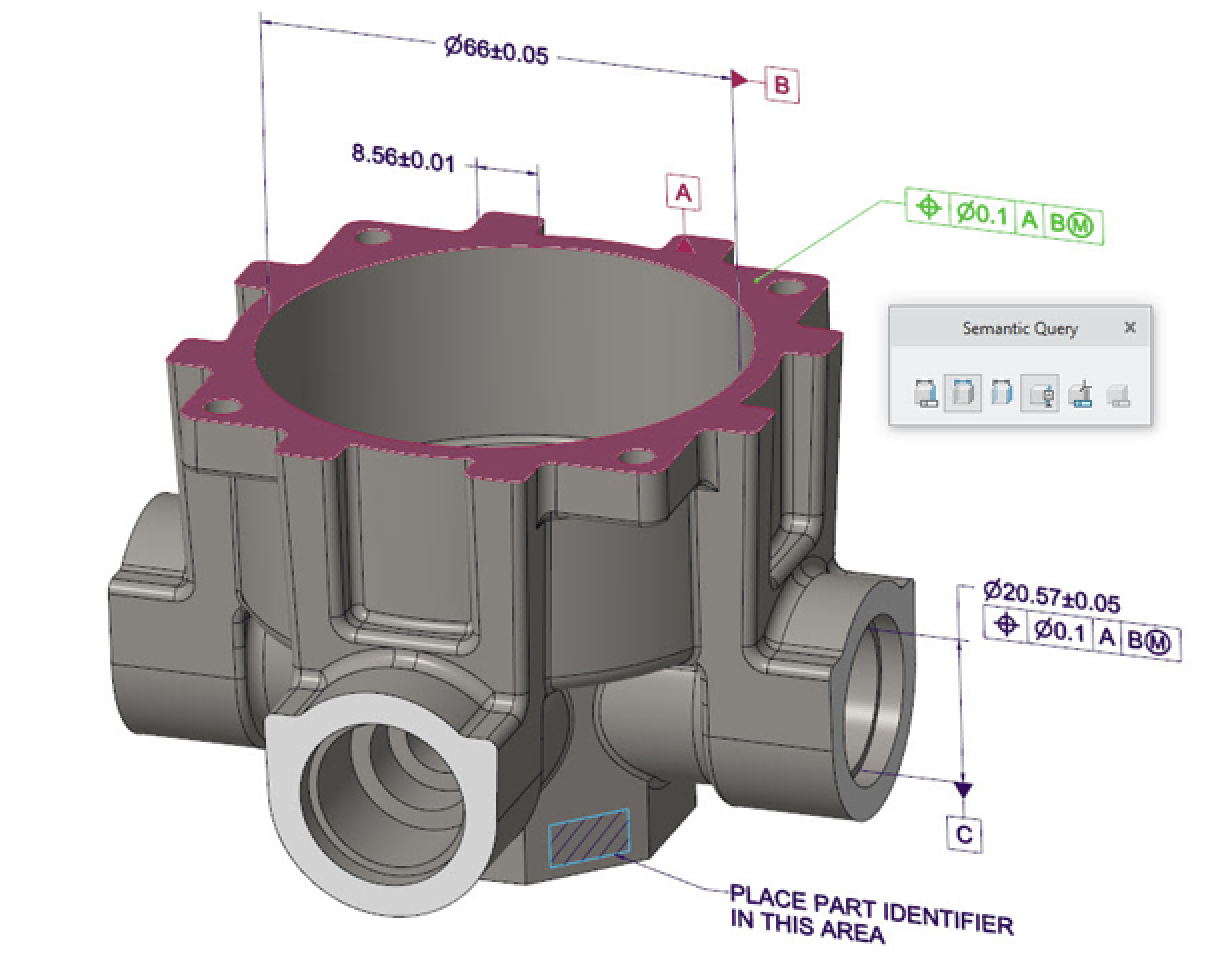

Model-Based Design (MBD) in Windchill transforms product development by using a 3D model to define all aspects of a product. All product data is stored in a central, secure repository, ensuring that configurations, variants, and revisions are visible across teams. When the 3D model is updated, Windchill automatically reflects those changes across configurations. Furthermore, every change to the model is tracked and versioned. This not only keeps data traceable but ensures all regulatory compliance standards are met.

In addition to viewing complex product assemblies in 3D, Windchill allows AR viewing. This enables users to interact with virtual models in real-world environments. These interactions help teams visualize the product without the need for physical prototypes.

BOM, Part Reuse, and Variant Management

BOMs

A well-structured Bill of Materials (BOM) is essential for managing complex products. Windchill’s configuration management features offer an intuitive way to handle BOMs, manage variants, and reuse parts. In Windchill, the BOM serves as a blueprint, offering a comprehensive view of the product. There are different types of BOMs including engineering BOMs (EBOMs), manufacturing BOMs (MBOMs), and service BOMs (sBOMs, not to be confused with Software BOMs). EBOMs reflect the product as designed by the engineering team, MBOMs focus on how the product will be assembled during the manufacturing process, and sBOMs are used for service and maintenance purposes. All types of BOMs keep track of product parts to ensure consistency.

Windchill can be used to link 3D models to the BOM, allowing teams to configure products more intuitively. It automates the generation of EBOMs directly from 3D CAD models. As designs evolve, the BOM is automatically updated, ensuring that changes in the 3D design are reflected accurately in the engineering documentation. Additionally, it can transform EBOMs to MBOMs or SBOMs to help transfer data across teams.

BOM and Part Reuse

In addition to transformation, Windchill also enables the reuse of BOMs. Reusing existing BOMs enables organizations to save time and money by leveraging previously developed parts. With Windchill’s BOM management, teams can easily search and identify the best components to reuse in new designs, reducing duplication and improving quality. This can also lead to faster development times, getting your products to market quicker.

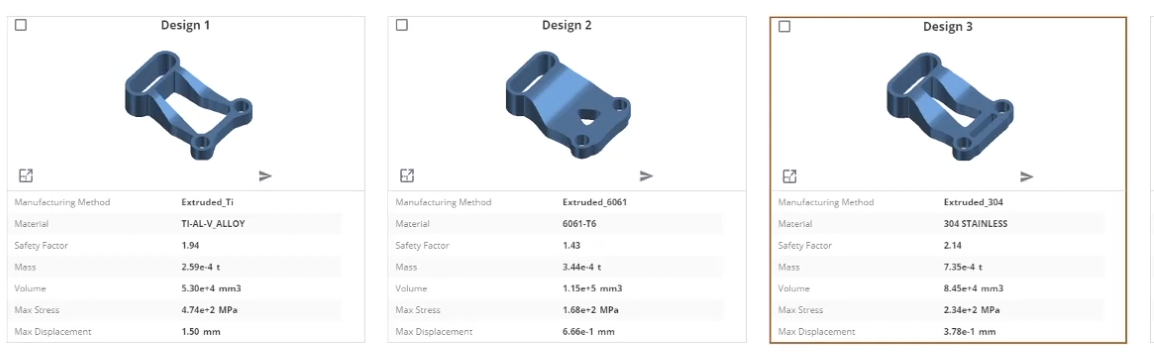

Variant Management

Windchill’s variant management capabilities further improve efficiency by defining variability based on product features. Rather than creating a new product from scratch for every variation, users can define the common core components (the platform) and customize aspects like size, color, or other functionality features. These platforms can be reused and slightly altered to minimize design errors and reduce unnecessary part generation.

Drive Innovation with Configuration Management in Windchill

Configuration management, powered by Windchill, is transforming product development by improving quality and compliance. By leveraging Windchill’s robust configuration management methodologies, organizations can better manage product data, variations, and parts. If you want to discover more about how Windchill can optimize your development, contact our experts today.