As technology progresses, many industries are taking advantage of these new advancements. The automotive industry is no exception. Automotive engineering has seen new trends emerge alongside digital transformation. Let’s dive into these trends and discover what we recommend to our clients in these industries.

Automotive Engineering Trends

The following trends are some of the most common goals for automotive companies currently.

- Electrification: Manufacturers are increasingly producing electric vehicles.

- Sustainability: Many automotive engineers are aiming to produce more sustainable cars, including electric and hybrid vehicles.

- Connectivity: This trend has a goal of creating a network. These networks range from car-to-car and car-to-infrastructure communication to the connection between vehicle occupants and the outside world. Essentially, the goal is to allow passengers to access the internet and work from their vehicle.

- Autonomous: Driverless vehicles are on the rise, allowing users to sit safely and comfortably while the car drives itself.

- Shared Mobility: The last trend is shared transformation services such as public transit, ride-sharing, and bike-sharing.

Automotive Engineering Challenges

With new trends also come challenges. Engineers aim to create lightweight designs to cut operating costs which often results in the use of resilient plastics rather than steel or aluminum. This can lead to microplastics entering the environment as well as plastic pollution at the end of life. In addition to this, safety and security are a main priority such as to prevent crashes, however, increased connectivity puts vehicles at risk for cyberattacks. Furthermore, the innovation of electric, connected, autonomous, and shared vehicles creates the need for continuous software updates and new models. Lastly, many engineers aim not just to be sustainable but to have a circular economy that uses regenerative design. Navigating these challenges can be tricky, but PTC’s range of products can help.

How PTC Tools Achieve Automotive Goals

While these challenges may appear difficult to overcome, they can be achieved with the right tools.

Data Storage and Traceability with Windchill

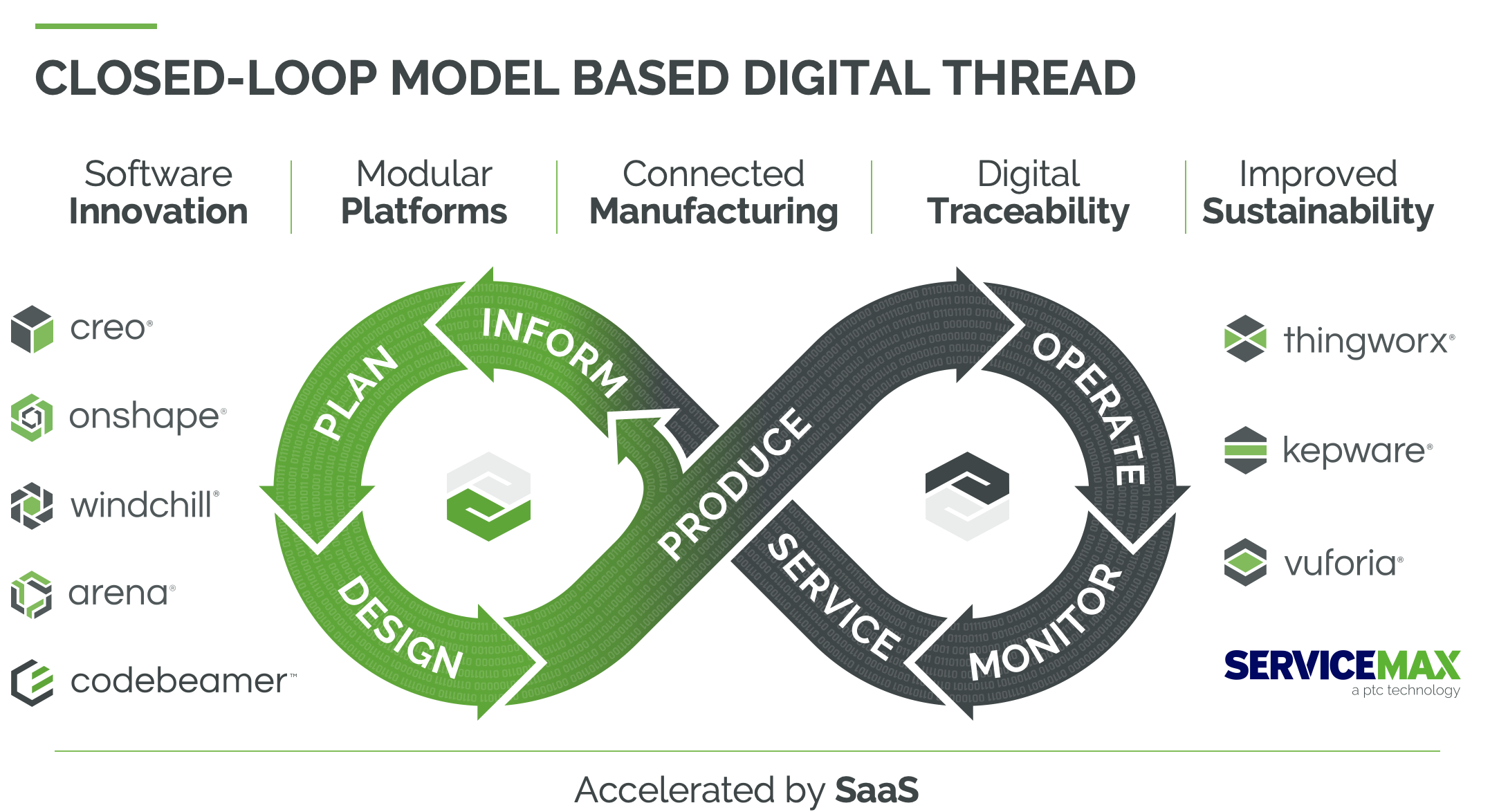

The first way PTC helps achieve these goals is by allowing organizations to have safe and organized data storage methods. PTC’s PLM solution, Windchill, combines with its field service management solution, ServiceMax, to create a closed-loop model. Windchill records and stores all digital product data while ServiceMax tracks the physical product serial numbers. This ensures every aspect of the entire product lifecycle is properly managed, preventing cyberattacks. In addition to this, these tools offer amazing traceability which helps ensure all parts meet safety and sustainability regulations.

Agile Development with Codebeamer

Codebeamer is PTC’s ALM solution offering many benefits to automotive engineers. First, Codebeamer allows automotive companies to consolidate multiple ALM landscapes into one solution, improving collaboration. In addition to this, Codebeamer offers amazing integration capabilities, allowing engineers to integrate their PLM and ALM solutions. Software is often the key differentiator in innovative products, making this benefit especially important. Furthermore, Codebeamer offers a modular design for predictable use. It also offers ready-to-use templates with predefined but adaptable workflows. Lastly, Codebeamer offers end-to-end traceability to ensure regulatory compliance.

Modular Platforms with Creo and Windchill

Another amazing feature of PTC products is their ability to support product variants. It is common for automakers to use modular platforms to build different models of cars using the same underlying architecture. A great example of this is platform sharing between mainstream and luxury brands such as Volkswagen and Audi. While one platform may be more upscale, the vehicle parts can often be the same. In addition to this, modular battery systems allow manufacturers to offer different battery capacities without redesigning an entire electric vehicle. PTC’s CAD solution, Creo, and PLM solution, Windchill, support these capabilities. Reusing components improves quality, eliminates duplicate parts, and saves money.

In addition to producing variants, Windchill can generate an mBOM matching a customer’s order and step-by-step 3D factory instructions that can be augmented onto a product. The manufacturing bill of materials is used alongside the instructions to connect the product engineering workflow to the manufacturing engineering workflow. It allows all information to extend to the shop floor, ensuring changes are managed properly throughout the entire lifecycle.

Sustainability

PTC offers sustainability practices through its partnerships and own tools. The company has a partnership with Ansys which offers material management capabilities early in the design process. Ansys helps design sustainable products by providing advanced simulation tools that enable engineers to produce sustainable designs. In addition to this PTC Creo offers generative design capabilities, allowing engineers to design lightweight parts and reduce material use. Manufacturing process planning can be implemented in Creo, Windchill, and Thingworx to improve manufacturability and cost, lowering your carbon footprint.

SaaS Offerings

The last benefit of PTC products we will cover is their SaaS offerings. 25% of PTC is now delivered as SaaS, including their CAD and PLM offerings, Creo+ and Windchill+. With software becoming the “brain” of products, the user experience, and the basis for monitoring, it is beneficial to offer SaaS products to keep up with digital transformation.

The Future of Automotive Engineering

New trends emerging alongside new technologies have created room for opportunity as well as new challenges for automotive engineers. Fortunately for PTC users, their wide range of tools helps resolve issues regarding cybersecurity, compliance, sustainability, and software. Discover how PTC products can help your team today.